History Of lime plaster

Lime in the history of architecture

As a general rule, lime or gypsum were used as the basical materials for the preparation of mortars and ancient binders.

VI millennium b.c; The use of a binder, coming from calcined rocks, was attested in the Catal Hôyûk site, south western Konya (Turkey) which was inhabited since neolithic times.Excavations shown gypsum- made coatings preserved on the walls.

V millenium b.c; In Mesopotamia, the first marks of lime-built constructions were discovered. In Uruk (nowadays Warka), the town of Gilgamesh; buildings with religious character (such as the "White temple") built with raw bricks, layered with lime water, together with a covering of mosaïc, were discovered.

III millenium b.c; Precolobian America mastered the manufactures of lime and its utilisazion in mortars, used as lining material. Raw material was obtained by burning shells. Precolombian mortars were made of lime and sand, sometimes gravels were present, too. The Mexico walley mortar, very hard, is considered as a "cement". Ancient Egypt, more or less at the same time, used poor gypsum made mortars for filling the holes in the cyclopean buildings (tumbs and step pyramids, Saqqarah region and Abydos). Lime, as lime water, was used as a pigment.

1900-1600 b.c;. In Creta, the minoean civilization, which stood under the influence of oriental art, lime-made frescos and stuccos were preserved (Palace of Cnossos). Then, these models were reproduced and adapted by the Mycenian civilization

700 b.c .: Arcaïc Grecia appealed to the stucco technics in the first temples, made of tuf, in Delphes and on the Hecatompedon of the Acropolis (Athenes). Before recieving a function of decoration, these stuccos were used for hidding defects of the masonery and to protect the surfaces of weak materials ( such as tufs, shelly limestones).

400-300 b.c. The use of such materials was limited to the so-called "poor" architectural elements: clay-made and rubble-made walls, it then expanded to house building. In stucco binders, some millimeters of lime or plaster together with marble sand were layered on clay-made walls or, more often, on a support made of a layer of lime mortar, such as in Priene, Delos and Thera.

320 b.c Hellenistic Grecia has widely expanded the use of plaster used as wall coating and as of house decoration which was until now reserved for civil and funeral architecture. Painted coatings and brush-made coatings were generalized; their characteristics were the colours richness and the multiplication of motives. Lime mortars are attested in the building of the Asian hellenistic kings, palaces, for example in Pergama (Turkey). Hellenistic Egypt followed the Greeks'building method; lime and gravel mortarswere used, sometimes associated with ground clay.

But Greek builders preferred to reserve their binding materials for coatings and wall-covering. An extreme care was taken when treating hydraulic installations: water tanks, basins, harbour areas and wall feet were coated with a waterproof mix of lime, sand and pouzzolanas (Santorin-Thera earth) or pumice stone, (Asclapieion basin at Gortys, water tank at Epidaure, exterior walls of Delos).

--------------------------------------------------------------

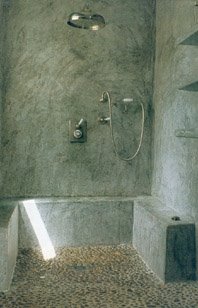

Tadelakt is known as the Stucco Lustro in the Italian tradition of elegant luxurious wall finishes. It is a real pleasure for those who love natural smoothness and is addictive. Its smooth and luminous surface exudes a hard to describe fascination which almost nobody can escape. The way th

Tadelakt is known as the Stucco Lustro in the Italian tradition of elegant luxurious wall finishes. It is a real pleasure for those who love natural smoothness and is addictive. Its smooth and luminous surface exudes a hard to describe fascination which almost nobody can escape. The way th